Pioneering PEF in Microalgae Applications

Algae +

2024 - 2025

Algae+ brings together Algae Holland and Elea Technology GmbH to unlock the full potential of microalgae using pulsed electric field (PEF) technology. With rising demand for lipids, proteins and pigments, PEF offers a breakthrough: ultra-short electrical pulses gently open cell membranes, releasing valuable compounds more efficiently and sustainably.

Towards an industrial-scale PEF system for sustainable microalgae extraction.

Innovation in Action

Trialing Microalgae

The project began with initial trials on Chlorella vulgaris, providing valuable insights into the extraction process. Building on these results, upcoming phases will test further microalgae species and explore different PEF parameters to optimise yield and quality.

Power of Collaboration

The project thrives on partnership. Algae Holland contributes expertise in microalgae cultivation, while Elea provides world-leading PEF know-how. Together, they are transforming scientific innovation into scalable industrial solutions.

Industrial PEF system for microalgae processing

The vision is clear: integrate an industrial-scale PEF system into Algae Holland’s production. This will expand their portfolio with premium algal extracts, while Elea demonstrates PEF’s potential in new sectors.

Algae+ is shaping the future of sustainable food and bio-based products – smarter, faster, and greener.

Bringing lab innovations to real food, using PEF and a new treatment chamber to turn advanced algae processing into sustainable, nutritious ingredients.

ENABLE

2024 - 2025

From ALGAE-MODULE 4.0 to ENABLE

The ENABLE project builds on the achievements of ALGAE-MODULE 4.0, where researchers developed new ways to grow and process microalgae such as Chlorella zofingiensis and Limnospira maxima. ENABLE now takes the next step: moving from the laboratory into real food demonstrations. It is part of the NewFoodSystems innovation space, which follows an integrated approach to building sustainable value chains for future foods.

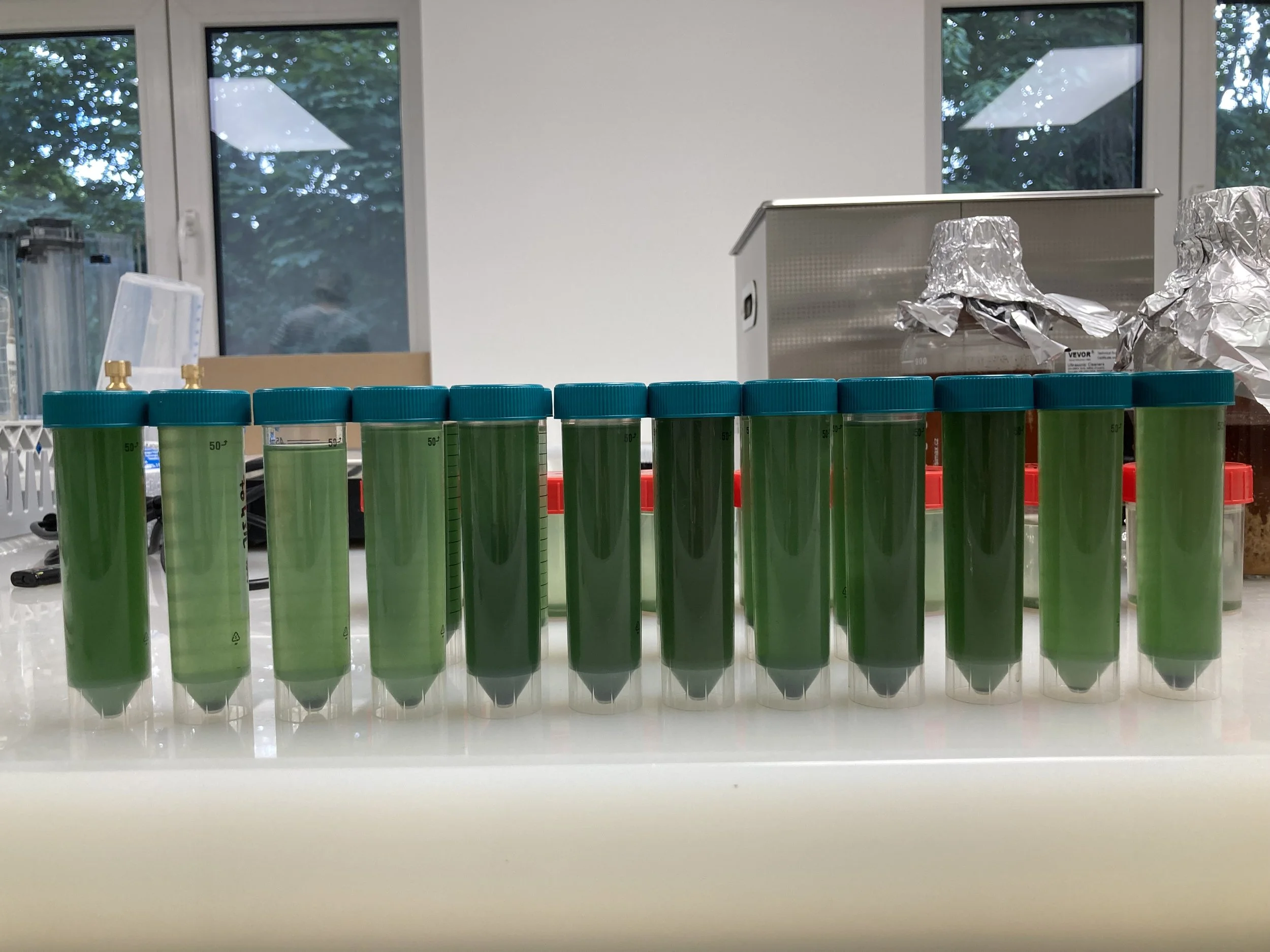

Spirulina SamplesPEF Trialing at Puevit/Algenwerk

ELEA sent biotechnology experts Arisa Thamsuaidee and Martha-Sophie Crohn to Dresden to perform PEF trials on microalgae for the ENABLE project, in collaboration with Gerd Hilpmann from PUEVIT GmbH and TU Dresden. The trials involved testing different algae biomasses and provided hands-on insights into the initial effectiveness of gentle PEF processing. PUEVIT, known for producing highly efficient photobioreactors, hosted the experiments, showcasing innovative cultivation and harvest solutions for microalgae like Spirulina and Chlorella.

Why Chlorella zofingiensis?

This single-celled freshwater microalga contains many valuable nutrients, including natural colourants (carotenoids) and healthy fats (unsaturated fatty acids). It is also extremely versatile: it can be cultivated under different conditions (photoautotrophic, mixotrophic, or chemoheterotrophic). ENABLE explores how these cultivation strategies influence both the nutritional value and the cost-effectiveness of algae production. PEF is central to the project’s innovation. By gently opening algal cells, Elea’s technology enables the extraction of proteins, antioxidants, and pigments—such as phycocyanin and carotenoids.

This approach not only improves yields but also ensures that biomass retains its functional and nutritional properties, helping overcome one of the industry’s biggest barriers: limited access to fresh high-quality algae ingredients in sufficient quantities.

Processing algae without losing their valuable compounds is a challenge. ENABLE tackles this using pulsed electric fields (PEF). With the PEF Pilot Dual system, short electrical pulses gently open the algal cells, making it easier to extract carotenoids and fatty acids — while keeping them intact and active. For food producers, this means high-quality ingredients with less energy use.

Gentle Processing with PEF

Developing a New Treatment Chamber

A major innovation in ENABLE is the development of a new treatment chamber designed specifically for microalgae. This work is led by ELEA, the project’s PEF technology provider, together with the German Institute of Food Technologies (DIL). The new chamber is designed to make the PEF process more efficient, scalable, and suitable for industrial applications, bridging the gap between research and real-world use.

Carl Felix Terheyden and Marc Schmidt trialing algae with PEF Pilot Dual at Puevit/Algenwerk.

Collaboration across Disciplines

ENABLE brings together experts from different fields:

TU Chemnitz & TU Dresden – process design, system modelling, and project coordination

ELEA & DIL – PEF technology provider and chamber development for algae processing

PUEVIT GmbH & Algenium GmbH & Co. KG – advanced algae cultivation in controlled environments

BTU Cottbus-Senftenberg – testing product safety with human cell models

By combining engineering, biology, and food science, ENABLE follows the holistic NewFoodSystems approach to create both new technologies and safe, nutritious products.

The Project Partners:

Collaboration beyond the borders of a research framework.

Puevit/Algenwerk at the Elea PEF Advantage Day 2024.

Algae Module 4.0

2022 - 2024

Shaping the Future of Algae-Based Foods with a Continuous Modular Production Facility for Fresh Algal Biomass and Ingredients.

Collaboration at the Core

The ALGAE-MODULE 4.0 project, initiated by NewFoodSystems, brings together research and industry partners to unlock the potential of algae in food. As a technology provider, Elea contributes its expertise in pulsed electric field (PEF) processing, supporting new ways of turning microalgae into valuable ingredients for sustainable food applications.

Through the complementary and interdisciplinary expertise of the academic partners

TU Berlin (downstream concepts, food technology) and TU Dresden (bioprocess engineering) –

together with industry partners

DH Licht GmbH (spectrally adjustable LED technology), Bruker Optik GmbH (NIR spectroscopy), Algenium GmbH & Co. KG and Puevit/Algenwerk (algae production and process monitoring), Elea Technology GmbH (cell disruption methods), endori food GmbH & Co. KG (plant-based meat alternatives) and Experior Micro Tech GmbH / Cultinova (process automation),

the project covers the entire process chain and drives new innovations within NewFoodSystems.

© NewFoodSystems/ Janosch GruschczykModular Algae Production

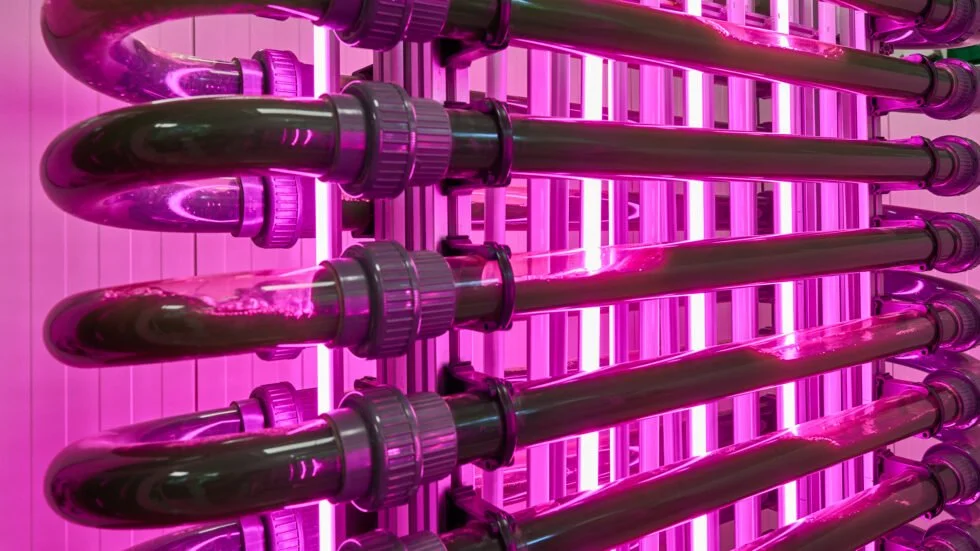

A key goal of the project is the development of continuous, modular production units that can be integrated directly into industrial food settings. Unlike conventional batch systems, these units enable the ongoing cultivation and processing of algae biomass at the site of use, ensuring a steady supply with precisely defined and consistent properties for local value chains.

By avoiding drying, storage, and long transport routes, the continuous approach promises higher-quality food ingredients with lower energy use—making algae processing both more efficient and more sustainable.

Sofie Schröder, Biotechnologist at Elea, trialing microalgae with PEF Pilot Dual

Power of PEF Technology

The project makes use of the Elea PEFpilot Dual system, a versatile processing unit that allows precise cell disruption and extraction under controlled conditions. This system enables researchers and industry partners to explore PEF treatment parameters in detail and optimise processing for continuous algae production.

PEF is central to the project’s innovation. By gently opening algal cells, Elea’s technology enables the extraction of proteins, antioxidants, and pigments—such as phycocyanin and carotenoids.

This approach not only improves yields but also ensures that biomass retains its functional and nutritional properties, helping overcome one of the industry’s biggest barriers: limited access to fresh high-quality algae ingredients in sufficient quantities.

Research is centred on two promising species:

Arthrospira platensis – the cyanobacterium commonly known as spirulina.

Chlorella zofingiensis – a microalga valued for its bioactive compounds.

From a process engineering perspective, the project is shifting from state-of-the-art batch operation to continuous production of algal biomass. Adjustable LED lighting allows growth and biomass composition to be tailored during cultivation, enabling fine-tuned nutritional and functional outcomes.

From Species to Solutions

Smart and Safe Processing

To ensure consistency, quality and safety, the project integrates real-time monitoring tools. Near-infrared spectroscopy, optical cell density detection, and contamination monitoring are linked to a digital quality system, enabling continuous oversight of both biomass and process performance.

The Project Partners:

iAlgaePro

2014 - 2017

International collaboration to unlock microalgae’s full potential using Elea’s Pulsed Electric Field (PEF) technology for growth stimulation, gentle extraction of high-value compounds like phycocyanin, and effective microbial decontamination.

Harnessing the “green gold” of the future

2014-2017, coordinated by the Research Association of the German Food Industry (FEI) and involving partners in Germany and Belgium, iAlgaePro united research institutions including the German Institute of Food Technology (DIL), the Institute for Food and Environmental Research (ILU), and technology providers such as Elea.

The project explored sustainable cultivation and processing of Spirulina platensis, Scenedesmus dimorphus, and other microalgae to produce functional proteins, natural pigments, and bioactive compounds for food and feed.

PEF system and integration

An Elea 5 kW continuous pilot-scale PEF system for liquids and semi-liquids was coupled directly to a Mesh Ultra-Thin Layer (MUTL) photobioreactor, enabling both continuous stimulation of cultures during growth and short-batch treatments for screening optimal energy inputs. This integration allowed precise testing from lab to pilot scale.

1. PEF for growth potential

Low-intensity pulsed electric fields enhanced biomass productivity and improved the nutritional profile. Mesh-Ultra-Thin-Layer (MUTL) cultivation combined with continuous PEF stimulation increased antioxidant capacity, polyphenol content, and altered fatty acid composition — producing algae with enhanced nutraceutical potential compared to reference methods.

PEF treatment facilitated gentle cell disintegration, releasing higher yields of proteins, enzymes, and pigments without chemical solvents or added enzymes. A striking example was phycocyanin extraction from Spirulina:

Control: 0.2 mg/ml

PEF-treated: 66.4 mg/ml

This represents an over 330-fold increase in yield, while preserving pigment quality. Phycocyanin is the only natural blue colourant approved for food without E-numbers, valued at up to €3,800/kg depending on purity.

2. PEF for extraction

Inactivation trials demonstrated that PEF effectively reduced microbial contamination in fresh or stored biomass, ensuring suitability for food applications while maintaining heat-sensitive nutrients.

3. PEF for decontamination

The project extended into practical trials, producing algae-enriched crackers, ice cream, chocolate, pasta, and snack products. Consumer studies indicated a clear preference for certain algae formulations, supporting the pathway from lab innovation to market-ready concepts.

From research to real products

Microalgae enriched crackers

By combining MUTL cultivation, membrane-based harvesting, and energy-efficient separation (achieving up to 70 % energy savings), the iAlgaePro consortium demonstrated a model for European microalgae production that is both sustainable and competitive, reducing dependency on imported biomass.